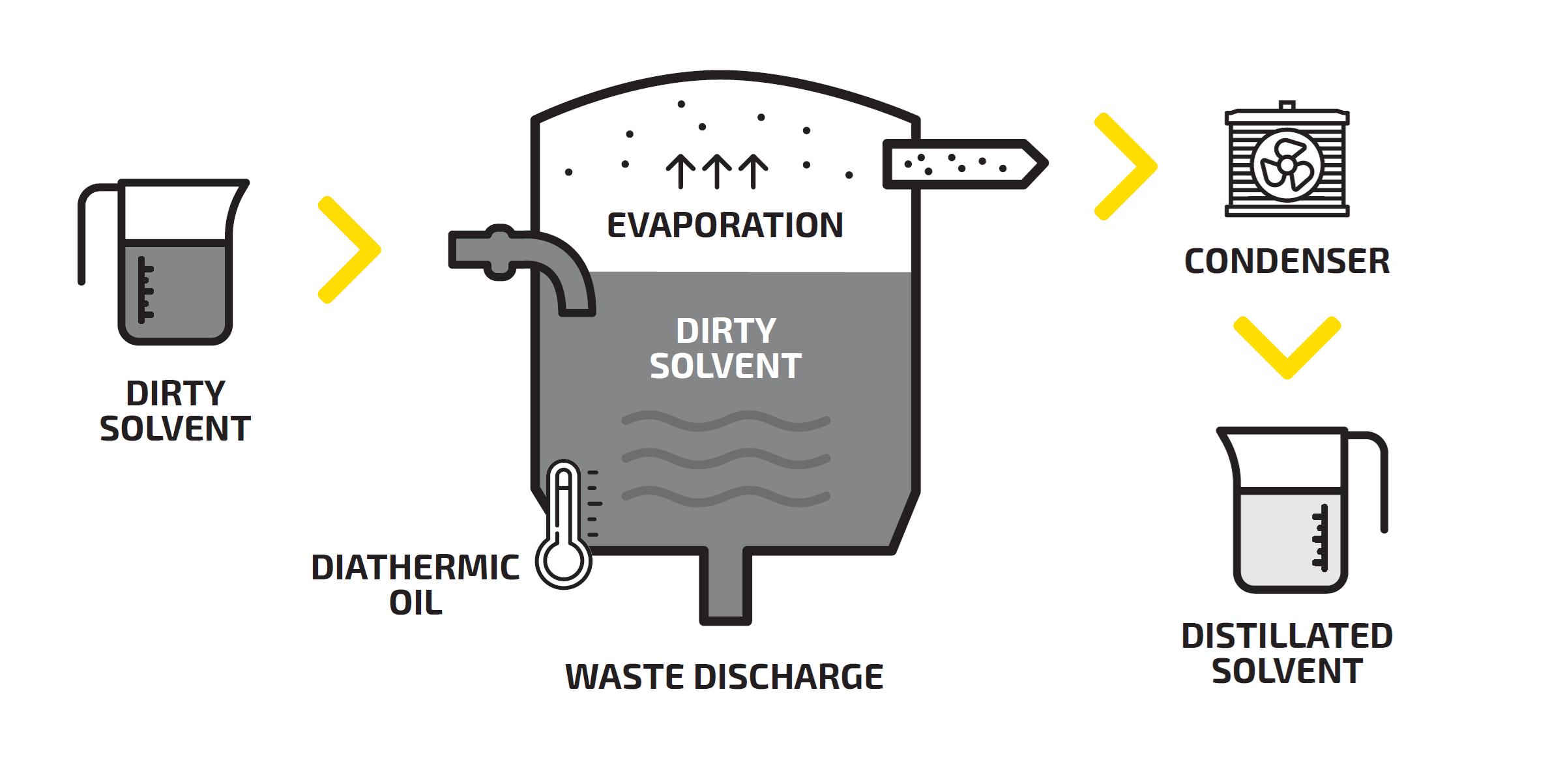

The recovery process of solvents is conducted inside solvent distillators.

About the process

Distillation is the process of vaporizing a liquid by heating it and then condensing the vapor on a cold surface. Distillation relies on the fact that different liquids vaporize at different temperatures (they have different boiling points). When heating a mixture of solvent and paint, the solvent begins to vaporize, but the paint residues do not vaporize at the same temperature. The vaporized solvent (or solvent vapor) is directed onto a cold surface where it condenses back into a liquid. However, the paint residues remain in their original container, as they do not vaporize. This process effectively cleans the solvent by separating it from the paint residues.

The distillators we rent and sell have physical dimensions of around 60cm*80cm, depending on the size of the machine. The equipment requires electricity (distillators larger than 60L tank require three-phase power supply). The distillation process is closed-loop, so there is not a significant emission of solvent vapors into the working environment. The machine generates noise at a similar level to that of a refrigerator. On average, one distillation cycle takes about 4 hours.

Inside the distillator, there are heat-resistant bags. Therefore, there is no need to clean the residual tank of the distillator after each use (the residues remain inside the removable bag).

There are also alternative technical solutions for solvent purification (such as purification using CO2 and various gases). However, gas-based solvent purification is complex and intended for the chemical industry. There are also distillators suitable for laboratory conditions. Estonian Tube Production OÜ specializes in distillators suitable for the metal industry, furniture industry and every other company that own painting equipment. The performance of the solvent distilling machines offered ranges from 10L to 2,500L per day.

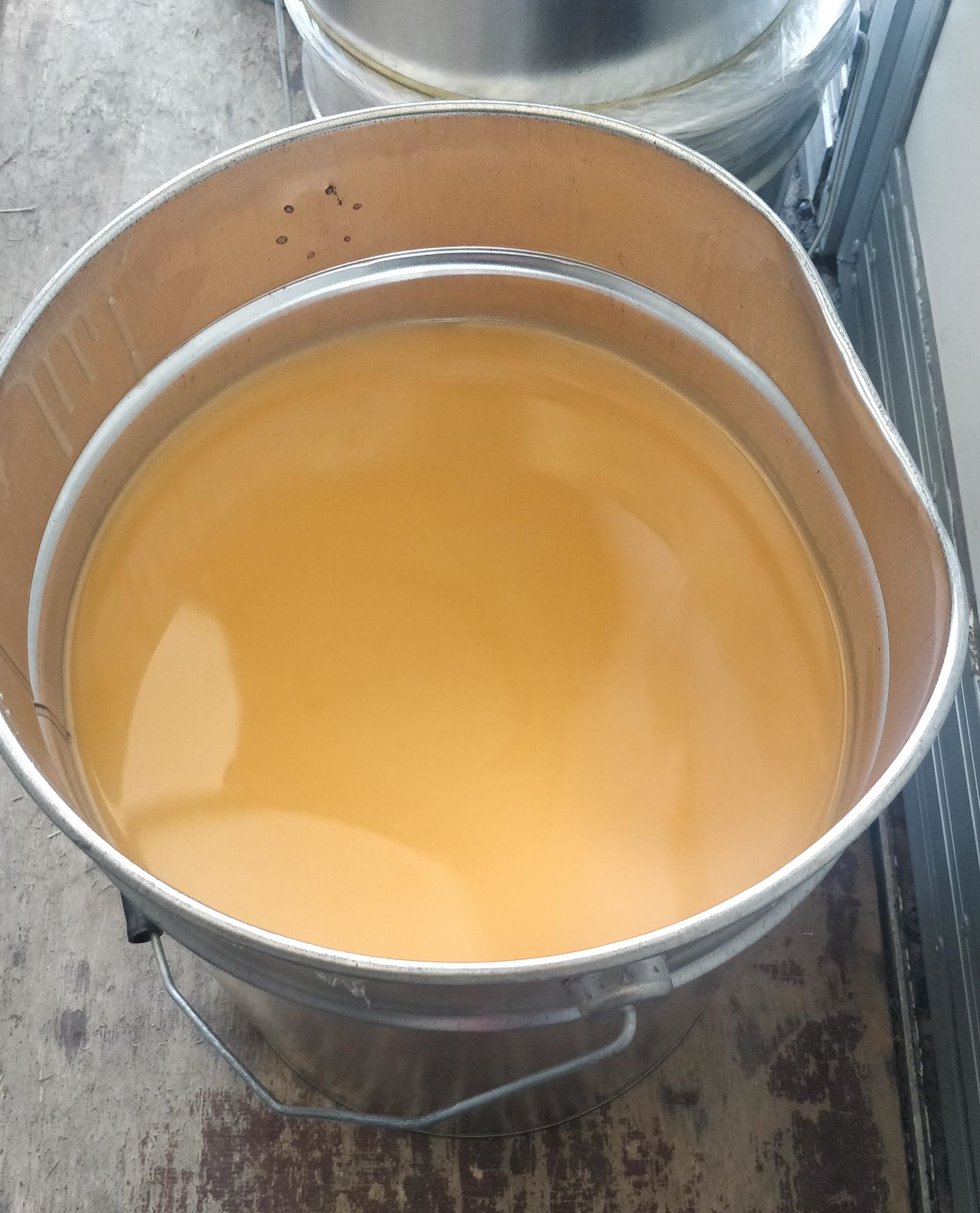

Solvent waste before distillation

Used Solvent Before Distillation inside the reclaiming machine (distillatory)

Removal of residues from the still after distillation

Consistency of end residue can vary depending on distilled chemicals.

Reclaimed solvent

The properties of the solvent resulting from distillation have not deteriorated. It is possible to distill the solvent an infinite number of times. However, it is important not to mix several different solvents and chemicals in the distillator. Different types of solvents should be collected and distilled separately.